What is Clutch

A Clutch is a mechanical device which when engaged transmits power from one shaft to another coaxial shaft. It engages and disengages the power transmission from the driving shaft to the driven shaft. When the clutch connects two shafts so then can rotate together, this phenomenon is called engaging of the clutch. While both shafts are rotating with different speed(slipping) or not connected to each other, is called the disengaging phenomenon of a clutch.

Function of clutch

The simple function of a clutch is, when it engages, it connects two shafts and thus provides power transmission from one shaft to another shaft. Whereas when it disengages, it disconnects two shafts and stops power transmission. The Clutch connects the flywheel of the engine to the gearbox, so it transmits power from engine to gearbox. Here is some main function of the clutch is given:

- Engaging and disengaging the gearbox with the engine.

- Transmitting engine power to road wheels smoothly.

- Allowing the gear change without any damage.

Requirement of a clutch

The following are the basic requirements of a simple clutch:

- It should engage gradually to avoid sudden jerk.

- It should not slip while engaging and disengaging.

- The clutch should occupy minimum space.

- It should have a minimum of inertia.

- It should not be noisy.

Types of automobile clutches

In the automobile application, we use two types of clutch: 1. Friction clutch, 2. Fluid flywheel.

1. Friction clutch

Friction clutch works on the principle that when a rotating disc comes in contact with a stationary disc, the stationary disc starts rotating because of friction between them. This is used when a moving (driving) shaft needs to connect to another different speed or stationary (driven) shaft. So how it can synchronize the speed or transmit power from driving shaft to driven shaft. This is also divided into many categories, described below.

2. Fluid flywheel

Fluid flywheel works on the principle of transfer of motion between two members by means of a fluid. It synchronizes the speed of the driving and driven clutch by applying the pressurized fluid.

Types of the friction clutch

There are mainly five types of friction clutch:

Cone clutch, Single-plate clutch, Multi-plate clutch, Semi centrifugal clutch, Centrifugal clutch.

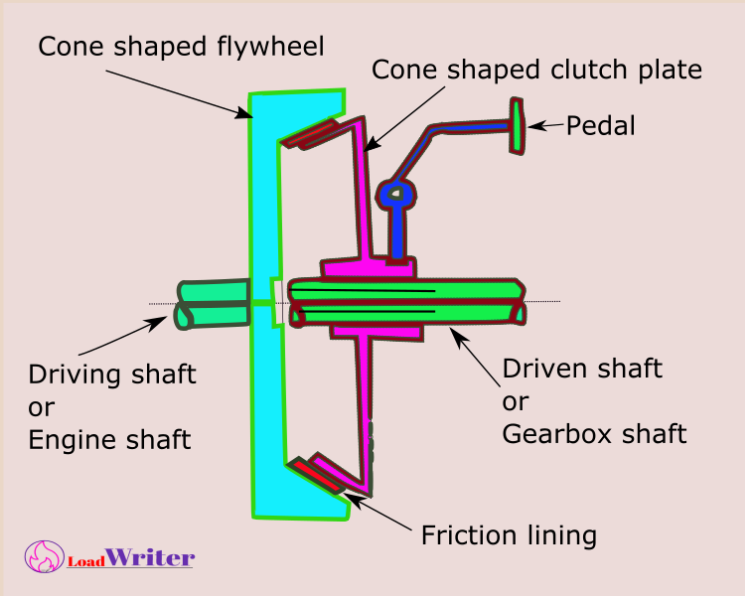

⇒ Cone clutch

In this type of clutch, a cone-shaped flywheel mounted on a driving shaft, and a cone-shaped clutch plate mounted on a driven shaft. Here cone-shaped clutch plate lined with friction lining. When the clutch engaged, the clutch plate moves inside to the flywheel, and the conical friction surface is complete contact. Thus torque gets transmitted to the gearbox shaft.

Cone Friction Clutch

For disengaging the clutch, the clutch pedal is pressed. When the pedal is pressed, it pulls the clutch plate and separates the contact surface between the plate and flywheel.

⇒ Single plate clutch

In this type of clutch, the clutch plate is placed between the flywheel and the pressure plate with the help of a coil spring during the engagement. Here clutch plate has friction lines and mounted on the splines and thus free over the gearbox shaft. The coil spring applies axial force and keeps the clutch in engage position due to axial force.

For disengaging the clutch, press the pedal which pulls the pressure plate outside and separates the contact surface with the flywheel. A single plate clutch is widely employed for heavy-duty vehicles. For example:- car, truck, bus, etc.

Single plate friction clutch

Nowadays a modified single plate clutch is used, known as a diaphragm spring type single plate clutch. It consists of a diaphragm spring attached to a pressure plate instead of a coil spring. Normally it’s a conical shape, but when assembled it get the flat condition, and thus it exerts a force on the pressure plate. So this force keeps the clutch in the engaged position.

⇒ Multi-plate clutch

The difference between a single plate and a multi-plate clutch is that the multi-plate clutch consists of multiple friction clutch plates attached to flywheel housing. It provides better and greater torque transmission compared to a single plate clutch. In ordinary conditions, these clutch plates remain engaged due to force applied by the pressure plate.

For space limitation, we use a multi-plate clutch by increasing the number of friction plates with a smaller diameter. A multi-plate clutch is used on light vehicles. For example:- two-wheelers, racing cars, etc.

⇒ Semi centrifugal clutch

The semi centrifugal clutch is used where high torque transmission is required. Here clutch is engaged with spring force as well as centrifugal force. It consists of a lever that hinged with a pressure plate. Now, at normal speed when power transmission is low, the coil spring keeps the clutch engaged. But at a higher speed when power transmission is more, the weight on the lever move outwards due to centrifugal action and thus act pressure on the pressure plate. So clutch firmly gets engaged and provides better transmission.

Semi centrifugal friction clutch

⇒ Centrifugal clutch

Here spring is eliminated and only centrifugal force is used to apply the required pressure for keeping the clutch in the engaged position. No clutch pedal is used as a clutch automatically disengaged below a certain speed. As speed increases weight flies and pressure plate get pressed. This force gets transmitted to the clutch plate and thus clutch plate engaged with the flywheel and transmits torque.

Read Also:- 65 Top Scientific instruments and Their Uses