The rotogravure printing machine is used for printing of the films (Polyester, PE, BOPP, OPP, Nylon), papers, and aluminum foils. This machine is also known as the gravure printing machine. Rotogravure printing is mostly used in the packaging industry.

Printing films or papers are called “web” in the packaging industry. In this printing process, liquid ink is used on the web with the help of an engraved cylinder. The rotogravure process is a type of intaglio printing process in which an engraved area holds ink and this ink is pressed on the surface of the web or printing plate.

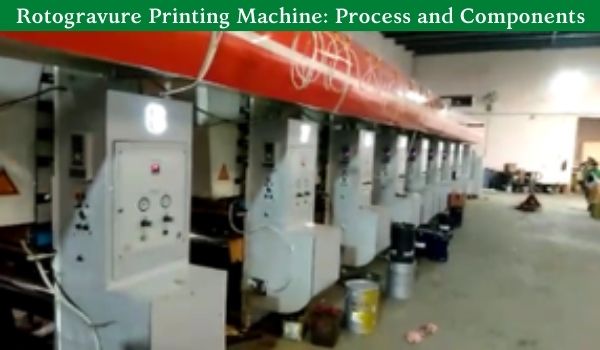

Gravure printing machines have different units that are known as printing stations. Each printing station is used to print material with different colors. According to the number of printing stations used, it is divided into many categories:

- Two-color rotogravure printing machine,

- Four color rotogravure printing machine,

- Six color gravure printing machine,

- Eight color gravure printing machine,

- Nine color rotogravure printing machine, and so on.

This machine can also be used for the coating of the films on one side or on both sides. For example, If we have 8 color job (film) and we also have to do coating on another side of the film, then we will use 9 color rotogravure printing machine. For printing this job firstly we will print at 8 stations with eight different colors and then turn the film and done coating at the 9th stations.

Main components of rotogravure printing machine

To understand the process of rotogravure printing machines, firstly we have to go through the main components of this machine. All parts of this machine play a role in the production and quality but few are the main components are described here:

1. Printing cylinder

The printing cylinder of the rotogravure machine is made of stainless steel, or aluminum, or composite material. On this cylinder, a design is engraved that have to be printed. The engraved printing cylinder is also known as a gravure cylinder.

2. Doctor blade

The doctor blade is used to remove liquid ink from the non-engraved position of the printing cylinder. It also used to remove excess ink from the engraved printing cylinder.

3. Sleeve roller

It is also called a rubber roller or impression roller. In this, a steel roller is covered with a rubber sleeve. Web or film pass between the printing cylinder and sleeve roller. So the sleeve roller presses the web against the cylinder and creates cylinder designed impression on the web.

4. Ink assembly

This assembly consists of an ink pan in which liquid ink is filled to print the films. Ink assembly also contains holding tanks, ink transmission pipes, and ink transmission pump.

5. Dryer system

The dryer system of the gravure printing machine is used for drying the printed film before reaching the next printing station.

Process of rotogravure printing machine

To print any film or web by the rotogravure printing machine a well-defined procedure is used.

Firstly all the ink pan is filled with different colors or coating at every station.

Designed printing cylinders are fit at every printing station.

The printing cylinder starts rotating in the ink pan and fluid ink is filled in the engraved position of the cylinder.

Excess ink in the cylinder is removed by the doctor blade, thus the doctor blade makes clean and clear to the cylinder except for engraved position.

A roll of the films comes in the contact of the cylinder and is pressed between the cylinder and sleeve roller.

Sleeve roller presses the film against the cylinder and transfers the impression of the engraved ink on to the film.

And that’s how a film or web is printed by ink in the rotogravure printing machine. It goes further for the drying in the dryer section.

This procedure is again repeated for further printing stations. All printing stations or units have different colors to print multi-color jobs.

Advantages of rotogravure printing machine

This machine for printing has the following main advantages:

- It has the ability to print with high speed, thus generates more production.

- Gives better print quality.

- As it needs a different cylinder for every color, so gravure printing is best for mass printing or high volume production but expensive for low volume production.

- It can be used to print paper, films like PE, BOPP, Nylon, Polyester, and other packaging print, magazines print, label print, etc.

- This machine also uses for repeatability process and cost advantages.

- Rotogravure printing is used mainly for printing on any packaging products such as films, magazines, postcards, corrugated fiberboard, etc.

- Printing cylinders can be used for long runs (stand for many years) for the specific job.

- Check Also: Clutch Function and Types of Automobile Clutch

- Check Also: Sliding Screen Doors